The 3 Inch/.50 Caliber Single Mark 34 and Twin Mark 27/33 Gun Mounts

By Robert F Sumrall (DD-762)

Early 1944 the Bureau of Ordnance began developing a 3-inch/50-cal. rapid-fire gun in both single and twin mountings. It was designed for use against the newer, faster, and heavier aircraft developed during World War 11 and especially the new jet-engined models. Suffering from postwar financial austerity, the first production models were not ready for the fleet until late in 1947 but the 3-inch replacement and conversion program was well underway when the Korean War began in 1950. Nearly all of the FLETCHER and SUMNER-GEARING classes had their 40-mm mounts replaced with the new 3-inch Mounts.

The 3-inch/50-cal. Mark 22 was a semiautomatic gun with a power driven automatic loader that fired a fixed AA (Anti Aircraft) or HC (High Capacity) round consisting of a projectile and a cartridge case crimped to the projectile. The average weight of the round was 34 pounds. The projectiles weighed about 13 pounds including a burster charge of 0.81 pounds for the AA round and 1.27 pounds for the HC round. The initial velocity of the round was 2,700 feet/second with a maximum range of 13,100 yards at 45 degrees elevation and a ceiling of 27,300 feet at 85 degrees elevation. The gun could fire at a rate of 50 rounds/minute.

The gun barrel was a monoblock cone-piece of alloy steel, rifled and chambered for fixed ammunition, and chrome plated for its entire length. The gun was secured to the housing, which contained the vertical sliding-wedge-type breechblock, with a bayonet type joint using interrupted screw threads. This arrangement greatly facilitated regunning. The gun and housing were supported by the slide, which allowed the gun to move in recoil and counter-recoil. A hydraulic cylinder stopped the gun recoil. A large counter-recoil spring returned the gun forward into battery. The power-driven automatic loader, consisting of a feed mechanism, a transfer tray, and a shell-carriage mechanism, each mounted on the after pan of the slide. It was a hopper feed mechanism with right, center, and left shaft-and-sprocket units. Ammunition was loaded into the right and left revolving sprockets that immediately moved the rounds to the center. The center sprocket alternated to accept a round from either side and in turn placed the round into the transfer tray and shell-carriage unit. The round was then lowered into line with the gun bore. The shell carriage was secured to an endless rammer chain that moved forward in the transfer tray, catapulting the round into the breech of the gun. Expended shell casings were caught in the ejection chute and directed forward away from the gun crew.

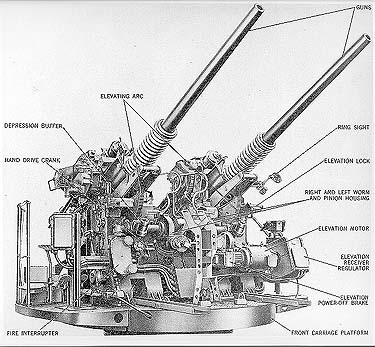

The new guns were fitted to both single and twin mountings. The single was to be exchanged for a twin 40-mm. mount and the twin for a quadruple 40-mm. mount. Although intended as a one-for-one replacement for the 40-mm. mounts, the final version of the new 3-inch mounts was heavier than expected, and on most ships the mounts could be replaced only on a two-for-three basis. The mounts were of the dual purpose, open-base-ring type. The right and left gun assemblies were identical in the twin mounts. The mounts used a common power drive that could train at a rate of 30 degrees/second and elevate from 15 degrees to 85 degrees at a rate of 24 degrees/second. The stands for both the twin and single mounts were virtually identical to the twin and quadruple 40-mm. mounts, respectively. This similarity greatly facilitated their installation. In many cases, however, the gun foundations below the stands had to be strengthened. Equipment mounted on the base ring and carriage above the stand included the gun pedestal, platform assembly, gun assemblies, and training and elevating mechanisms.

During the destroyer Fleet Rehabilitation And Modernization (FRAM) program of the 1960s the destroyers that were modernized had their 3-inch guns removed, however, those that did not undergo FRAM kept most of their 3-inch guns and as of this writing they survive in a few foreign navies.